Esnek Ambalaj nedir?

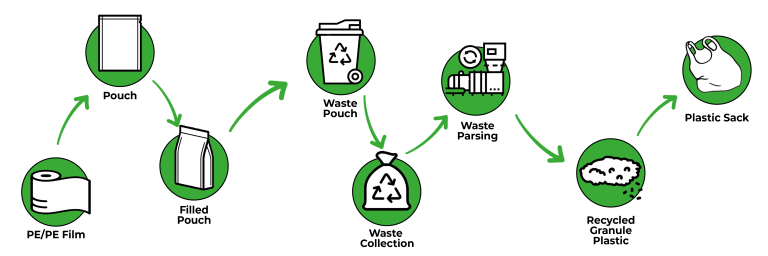

Geri Dönüştürülebilir Ambalaj

Krcpack Ambalaj, kaliteden ödün vermeyen esnek ambalaj sektörünün öncü ve yenilikçi markaları geri dönüştürülebilir ambalaj konusunda ciddi yatırımlar yapmaktadır. Geri dönüştürülebilir hammadde kullanımı ile ambalajlarımızın %100 geri dönüştürülmesini sağlıyoruz.

Temiz Dünya

Ambalajlarımızla temiz bir dünyaya adım atıyoruz. Geri dönüşüme uygun tasarımımızla çevreye duyarlılık gösterirken, sürdürülebilir malzemelerle üretim yapıyoruz. Temiz gelecek nesillere bırakma hedefimizle, doğa dostu çözümler sunuyoruz.

Tasarruf

Ambalajlarımız, tasarruf ve çevre bilincini bir araya getiriyor. Hafif ve verimli tasarımımız, enerji ve maliyet tasarrufu sağlayarak sürdürülebilir bir geleceğe katkı sunuyoruz.

Doğal Kaynak İsrafı

Ambalajlarımızla doğal kaynakları koruyoruz. Sürdürülebilir üretim ve geri dönüşüm yaklaşımlarıyla, kaynak israfını engellemek için sorumluluk alıyoruz.

Doğal ve Canlı Tasarım

Ambalajlarımız, doğanın sunduğu zenginliğe saygı göstererek geri dönüşümle buluşuyor. Sürdürülebilir malzemelerle tasarlanan ambalajlarımız, çevreyi koruma ve gelecek nesillere temiz bir dünya bırakma hedefimize destek oluyor.

Tazelik ve Koruma

Ambalajlarımız, özenle tasarlanmış yapısıyla ürünlerinizin tazeliğini ve kalitesini dış etkenlere karşı korur. Doğa dostu malzemeler ve geri dönüşüme uygun tasarımımızla, hem taze ürünleri sunuyor hem de çevre bilincine katkı sağlıyoruz.

İnovasyon

Ambalajlarımız, sürdürülebilirlikteki yenilikçi adımlarımızı yansıtıyor. İnovatif tasarım ve geri dönüşüm teknolojileriyle, geleceğe yönelik çözümler sunuyoruz.

Retort Ambalaj

Retort paketler et, balık, tavuk, peynir, hazır soslar, pişmiş hazır yemekler, çorbalar, mezeler ve evcil hayvan mamaları gibi gıda endüstrilerinde sıklıkla kullanılır.

Gıda şirketleri, üretilen yiyecekleri sağlıklı ve dayanıklı ambalajlar sayesinde maksimum güvenle tüketiciye aktarmayı amaçlamaktadır.

Krcpack olarak üç ve dört katmanlı laminasyonla dünya standartlarında retort ambalajlar üretiyoruz.

Dayanıklılık

Retort ambalajlar, yüksek sıcaklıklara karşı ürünlerinizi mükemmel bir şekilde korur. İleri teknoloji malzemeleri, bu ambalajları sıcaklığın etkilerinden korurken ürünlerin tazeliğini ve lezzetini muhafaza eder. Sterilizasyon işlemleri ve yüksek ısıya karşı dayanıklılıkları, retort ambalajları sıcaklığın önemli olduğu gıda, ilaç ve endüstriyel uygulamalarda ideal bir çözüm haline getirir.

Koruma

Retort ambalajlar, ürünlerin tazeliğini ve lezzetini muhafaza etmek için mükemmel bir seçenektir. Dayanıklı yapısı, dış etkenlere karşı üstün koruma sağlar. Sıcaklığa ve basınca dayanıklı olan retort ambalajlar, ürünlerin güvenli bir şekilde saklanmasını ve taşınmasını sağlar. Tüketicilere ürününüzün kalitesini ve güvenilirliğini garanti edin.

Raf Ömrü

Retort ambalajlar, ürünlerin raf ömrünü uzatmada mükemmel bir rol oynar. Sızdırmaz tasarımı ve yüksek sıcaklık dayanıklılığı, ürünlerin tazelik ve lezzetini korur. Bu ambalajlar, gıda endüstrisinde ürünlerin daha uzun süre raf üzerinde kalmasını ve tüketiciye daha uzun bir kullanım süresi sunmasını sağlar. Ürünlerinizi daha uzun süre boyunca mükemmel durumda tutmak için retort ambalajlarını tercih edin.

Tazelik ve Lezzet

Retort ambalajlar, ürünlerin tazelik ve lezzetini koruma konusunda mükemmel bir çözümdür. İleri teknoloji yapısı sayesinde, ürünlerinizin doğal lezzetini ve tazeliğini uzun süre boyunca muhafaza eder. Sızdırmazlık özelliği sayesinde dış etkenlerin ürünlerinize zarar vermesini engeller, böylece tüketicilere her zaman en iyi tadı sunar. Retort ambalajlarla ürünlerinizi taze ve lezzetli tutun.

Çeşitlilik

Retort ambalajlar, çok çeşitli sektörlerde güçlü bir varlık sunar. Gıda endüstrisinden sağlık sektörüne kadar, bu yenilikçi ambalajlar ürünlerin dayanıklılığını artırır. Hazır yemekler, ilaçlar, evcil hayvan mamaları ve daha fazlası, retort ambalajlar ürünlerin sağlamlığını ve uzun ömürlülüğünü garanti eder. Bu çok yönlü ambalaj çözümü, farklı sektörlerin ihtiyaçlarına uyum sağlamak için idealdir.

Hafiflik

Retort ambalajlar, ürünlerinizi korurken aynı zamanda hafif ve taşınabilir bir ambalaj seçeneği sunar. Dayanıklı malzemesi, ürünlerin güvenliğini sağlarken ağırlığı minimumda tutar. Bu hafif ambalajlar, taşıma maliyetlerini azaltır ve çevreye daha az etki yapar. Retort ambalajlarla, ürünlerinizi hafif ve pratik bir şekilde paketleyin, taşıyın ve sunun.